Features ...............................................................................................................................

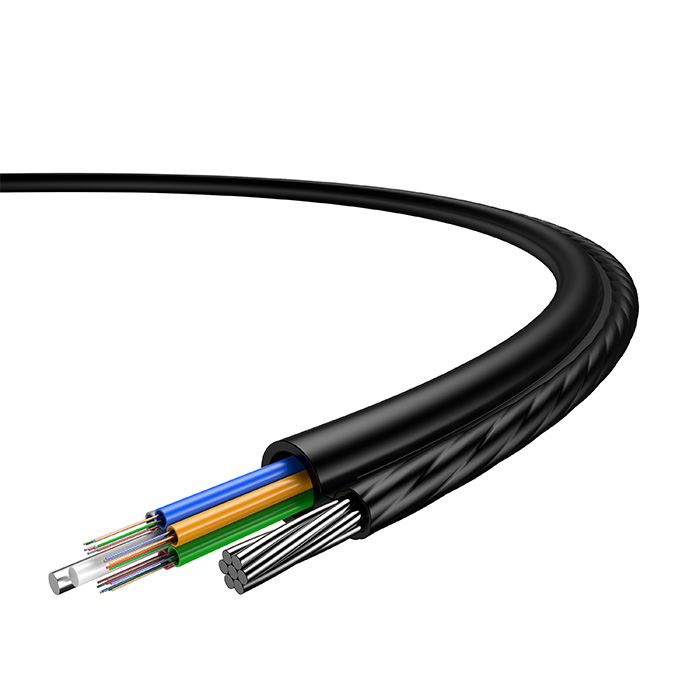

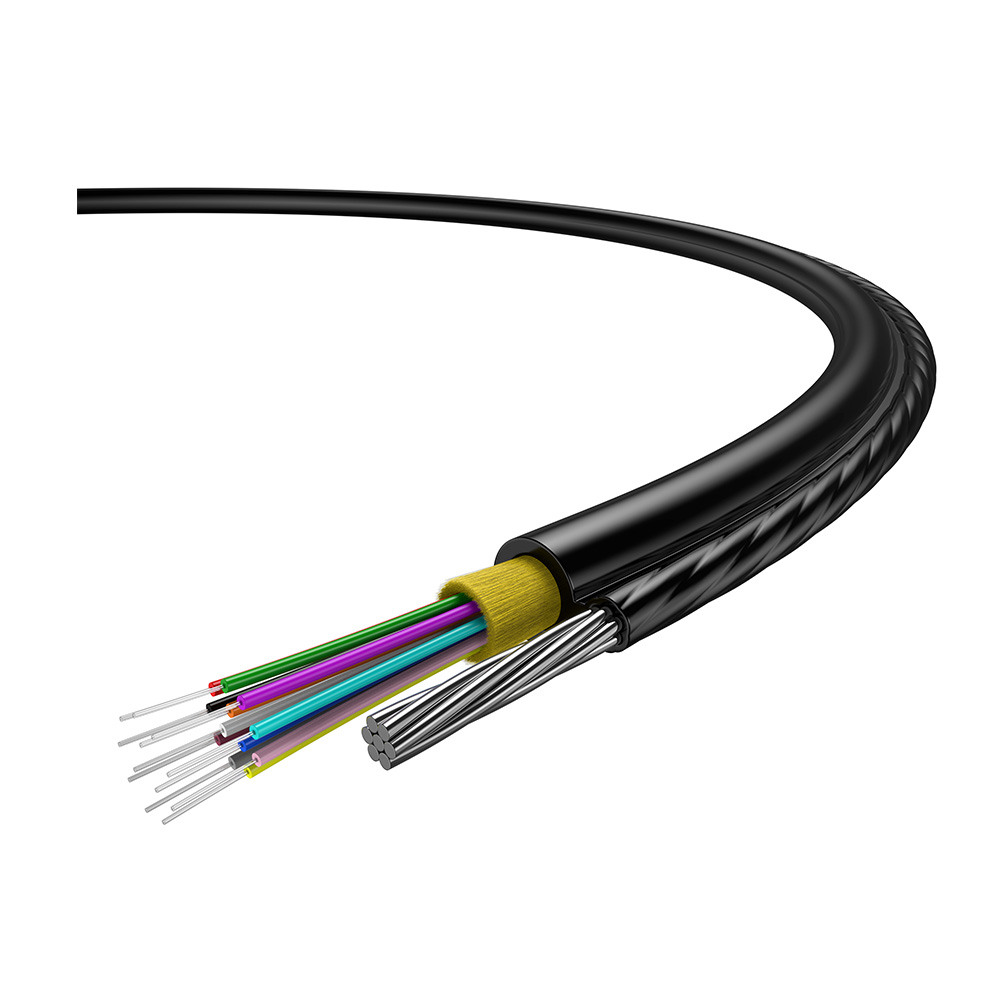

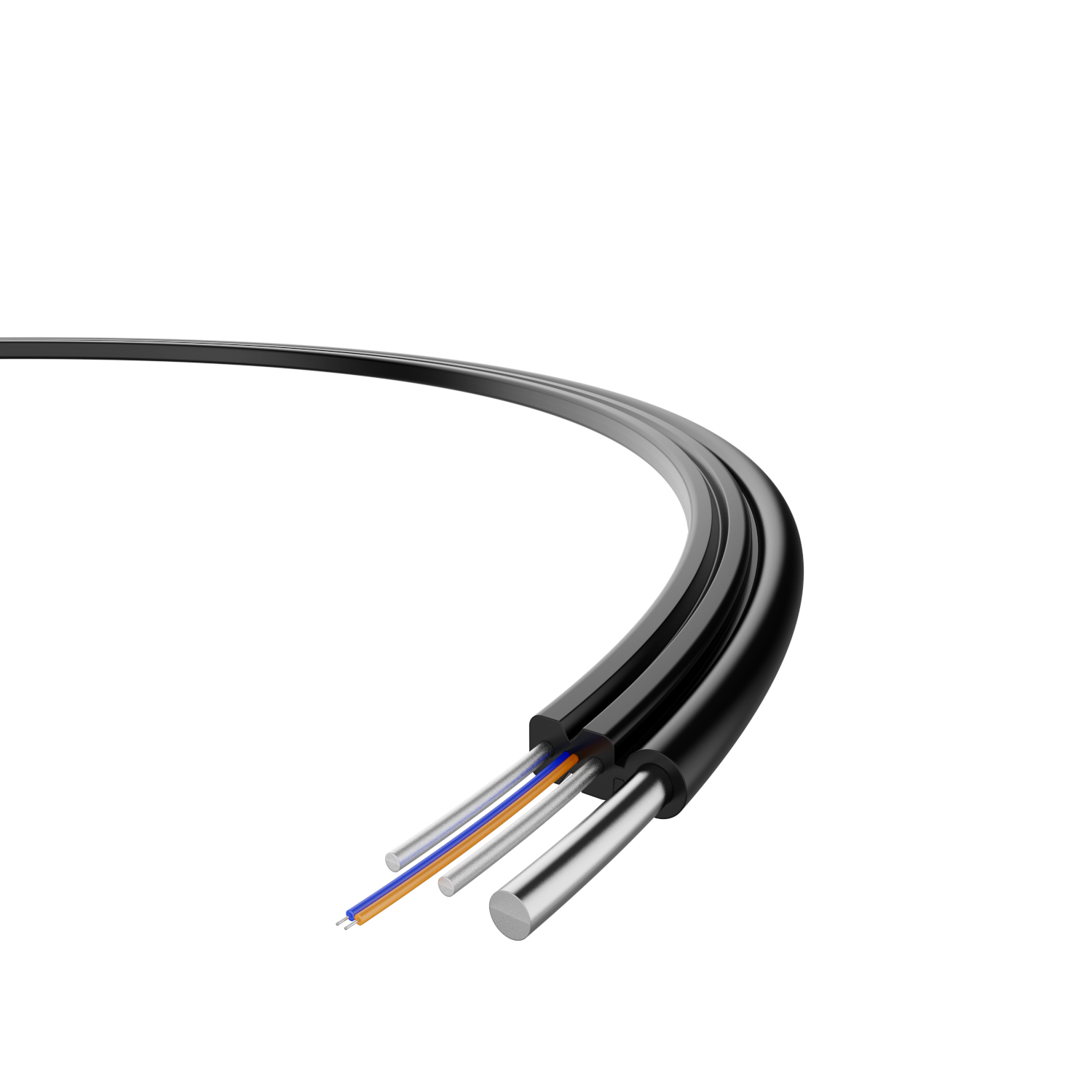

- Loose tube gel-filled construction for superior fiber protection.

- CST armor to protect the cable from rodent attack and mechanical damage.

- UV and moisture-resistant design.

- The high tensile strength of stranded wires meets the requirement of self-supporting and reduces the installation cost.

- Good mechanical and temperature performance.

- High-strength loose tube that is hydrolysis resistant.

- Special tube filling compound ensures the critical protection of fiber.

- The following measures are taken to ensure the cable is watertight: --- Steel wire used as the central strength member --- Loose tube filling compound --- 100% cable core filling --- APL moisture barrier.

Applications .........................................................................................................................

- Backbones and Access.

- Installed aerially.

Specifications .......................................................................................................................

| Fiber Count | Nominal

Diameter (mm)

|

Nominal

Weight (kg/km) |

Max Fiber Per Tube

|

Max No.of(Tubes+fillers) | Allowable Tensile Load (N) | Allowable Crush

Resistance (N/100mm)

|

||

| Short Term | Long Term | Short Term | Long Term | |||||

| 2~30 | 10.0×18.0 | 142 | 6 | 5 | 7000 | 4000 | 1000 | 300 |

| 32~48 | 10.7x18.8 | 155 | 6 | 6 | 7000 | 4000 | 1000 | 300 |

| 50~72 | 11.6x19.4 | 170 | 12 | 5 | 7000 | 4000 | 1000 | 300 |

| 74~96 | 13.0x20.0 | 192 | 12 | 6 | 7000 | 4000 | 1000 | 300 |

| >144 | Available upon customer’s request | |||||||

Fiberroom Services ........................................................................................................

- Any questions will be replied to within 24 hours.

- Professional manufacturer, Welcome to visit our company.

- 100% test before shipping.

- OEM/ODM is available (As required print logo and customized color).